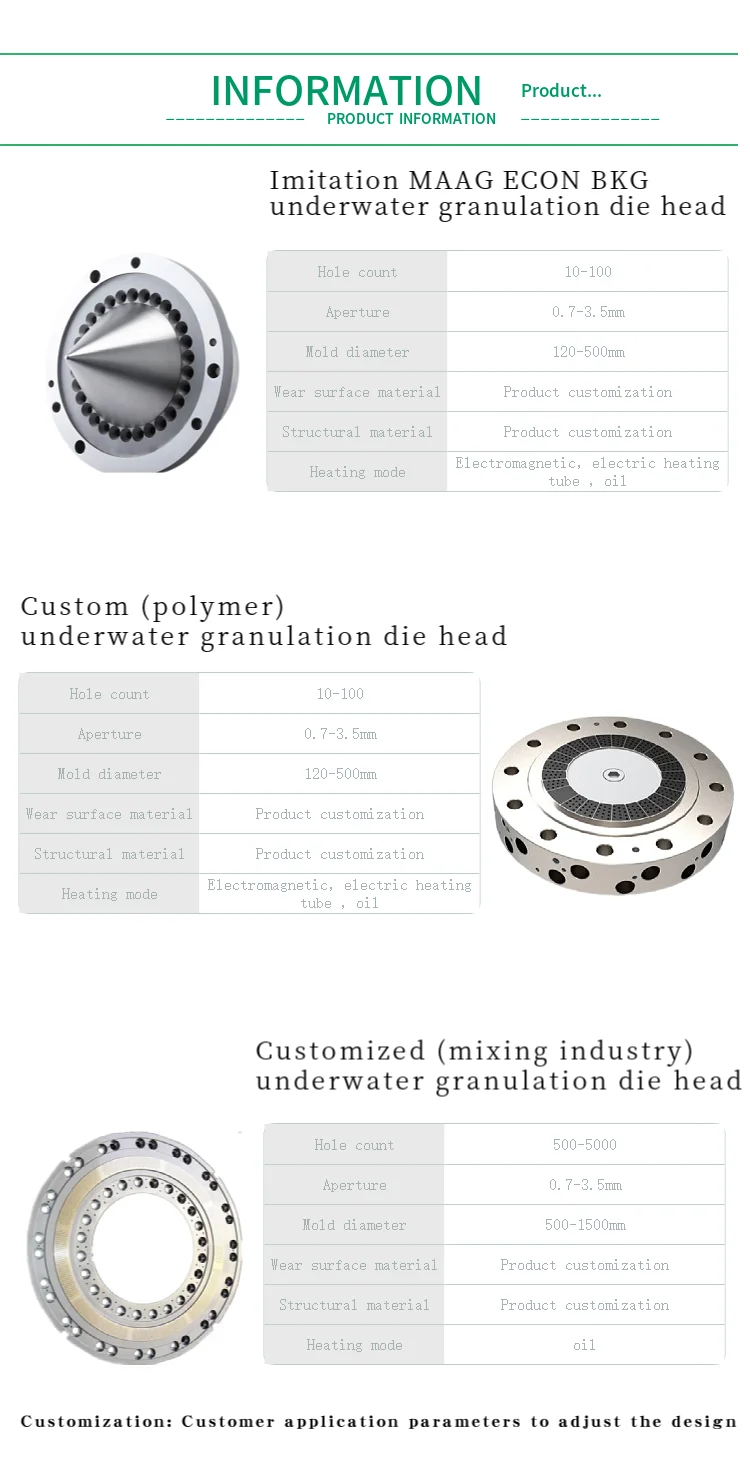

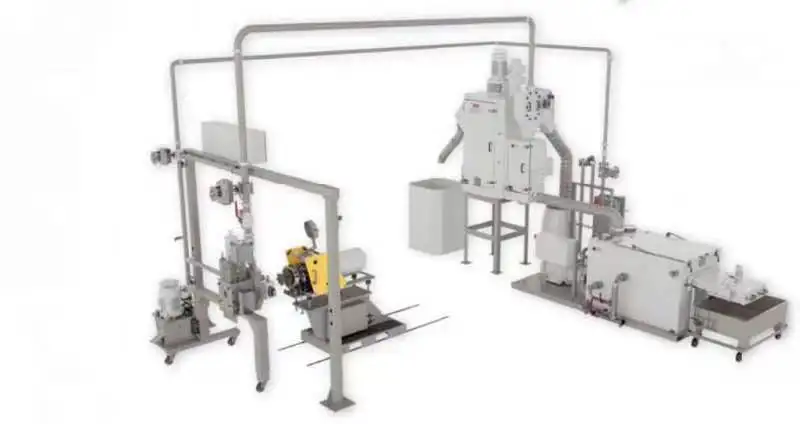

Products Description

TPRODUCT FEATURES.

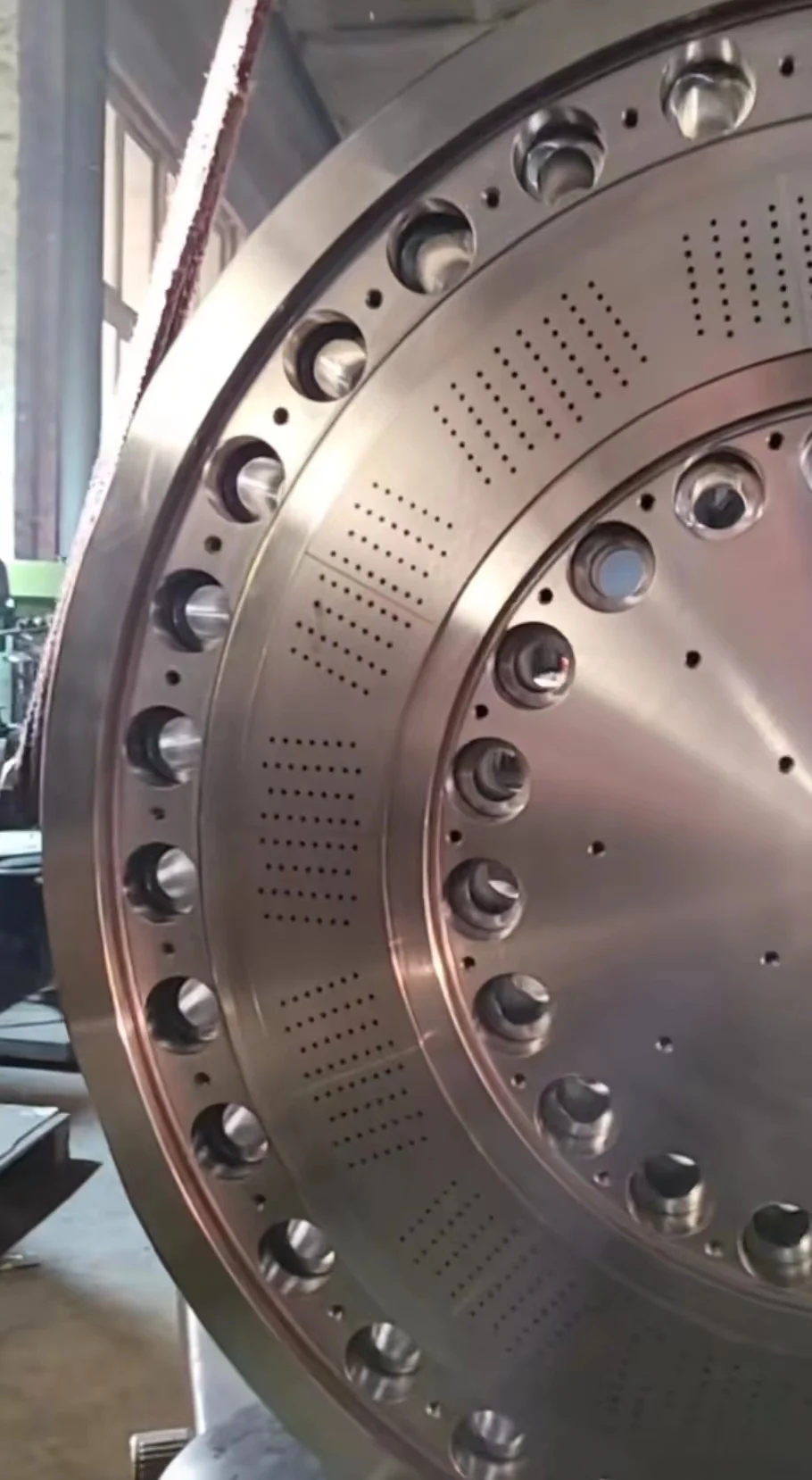

1. The process optimization of polymer flow

2. The die design of radial achieve ideal melt distribution

3. Without deflection without dead space design

4. The polymer melt directly sent to the cooling circuits

5. Good control of the melt until the forming of particles

6. Die hole flow optimization of heat conduction

7. Excellent thermal insulation of the die

8. Heat sensitive materials can be used for choosing the die face design

9. According to the material and capacity to choose properheating mode

10. Choose different material or coating, and the disadvan-tages of die design can reduce the wear and tear

11. The blade grinding online

12. The blade cooling circulation water

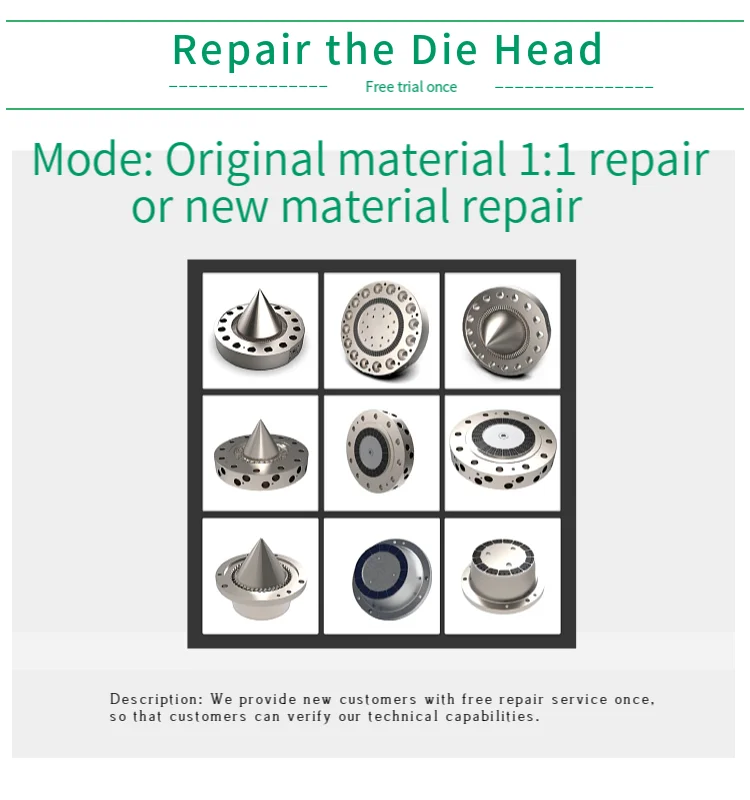

Our Services

import underwater pelletizing template , specializing inthe production and maintenance of water ring diced templates.template for use after repair effect and life quality is the sameas the imported, for many well-known domestic enterprisesto provide services for a long time, which also and extrudermanufacturers in Germany , Austria recycling machinerymanufacturers to establish a long-term cooperation , throughhigh quality products,improve the efficient after-sales service.

Applications

Scope of application

Granulators are ideal for the production of raw materials and for the manufacture of compound, mix, Masterbatch and recycled

materials from:

—–Polyolefin, such as LDPE, HDPE, PP

materials from:

—–Polyolefin, such as LDPE, HDPE, PP

—–Styrene polymers, such as PS, SAN, ABS

—–Acrylic resins, such as PMMA, PAN

—–Polyacetals, such as POM

—–Polycarbonate vinegar, such as PC

—–Poly cool, such as PET, PBT, PEN

—–Polycuramines, such as PA 6, PA 6.6, PA 11, PA 12

—–Thermoplastic elastomers, such as TPE-S, TPE-E

—–Polyurethane, such as TPU

—–Hot melt glue

—–rubber

—–Natural and synthetic resins

—–Biopolymers such as PLA, PHA, Bio-PA, Bio-PET, Bio-PP

—–Other plastics (upon request)

—–Acrylic resins, such as PMMA, PAN

—–Polyacetals, such as POM

—–Polycarbonate vinegar, such as PC

—–Poly cool, such as PET, PBT, PEN

—–Polycuramines, such as PA 6, PA 6.6, PA 11, PA 12

—–Thermoplastic elastomers, such as TPE-S, TPE-E

—–Polyurethane, such as TPU

—–Hot melt glue

—–rubber

—–Natural and synthetic resins

—–Biopolymers such as PLA, PHA, Bio-PA, Bio-PET, Bio-PP

—–Other plastics (upon request)

Company Information

How can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

Always a pre-production sample before mass production;

Always final Inspection before shipment;

What can you get from us?

Extrusion Tooling,Coextrusion Mould,pvc extrusion mould,wpc profile mould,plastic extrusion mould

Why should you choose us?

Jiade Company has accumulated over 25 years of experience in the technology of extrusion mould, from mould designing, production to commissioning. We have cultivated a mature team of personnel. Jiade Company applys the high-pressure low-turbulen.

What services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,CIP;

Accepted Payment Currency:USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T,L/C,D/P D/A,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken:English,Chinese,Japanese,German,French,Russian.